Automation

Integration

Scalability

Speed

Savings

The rise of the robots

As part of the efficiency improvement of the entire logistics component, in 2019 we have seen the introduction of new APS (Automatic Positioning System): automatic trolleys for the management of loading, unloading and picking operations. Thanks to this innovation, the expected results come from many different sides: savings related to the increase in storage density, improvement in the speed of loading / unloading operations, reduction of risks and errors, greater monitoring options and overall improvement of the quality of management.

The impact on systems and processes

To manage the success of this initiative, meduse and GFT have worked alongside managers and end users to design, develop and integrate a new system, able to centralize management of all warehouses, both in terms of logical mapping of environments and relationship between available spaces and types of products.

A new architecture have been optimized in relation to the existing application ecosystem: the system has been integrated with the local warehouse management applications for inbound and outbound handling of loads and has been prepared to guarantee scalability and modification of such systems, looking forward future developments.

The new system enables direct communication between the warehouse management system and automatic trolleys and, thus, the automatic handling of loads for operators, taking advantage of strategies that, in future, could be optimize through the introduction of artificial intelligence.

Let's stay human

Digital transformation, optimization of processes and automation of activities have to costantly face human beings to improve their working conditions and, therefore, their efficiency and productivity. meduse is committed in designing interfaces that reduce perceived complexity and improve processes and user experience at the same time.

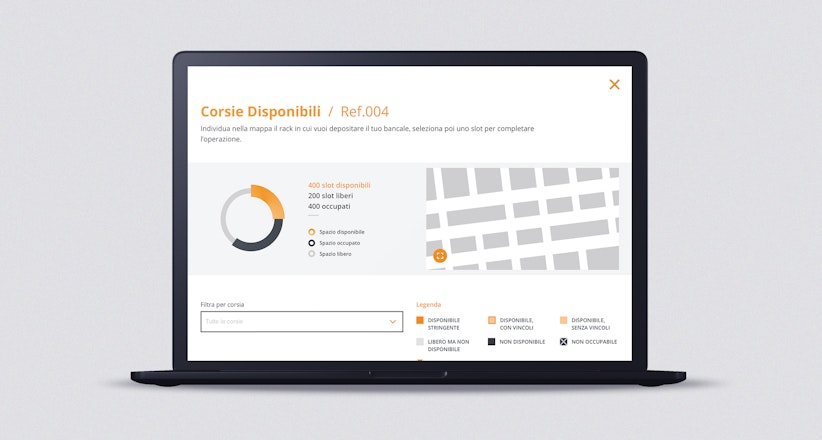

In the design phase, our effort focused on trying to define a graphical map able to eliminate the physical differences between the various warehouses by reducing the mapping of the storage system to an easy-to-interpret standard system. The result is a user interface that allows a quick analysis of the status of each warehouse sector, leading to a quick and effective choice of spaces and loads.

During the many years of collaboration with a brand that cares greately about work environment, meduse has built solid UX guidelines and UI elements, able to grant a coherent experience to both internal systems and the many digital touch points, fostering a consistent corporate image.